Fully-Auto Pre-Stretch Casting Film Wrapping Machine/Winding Packaging Machine

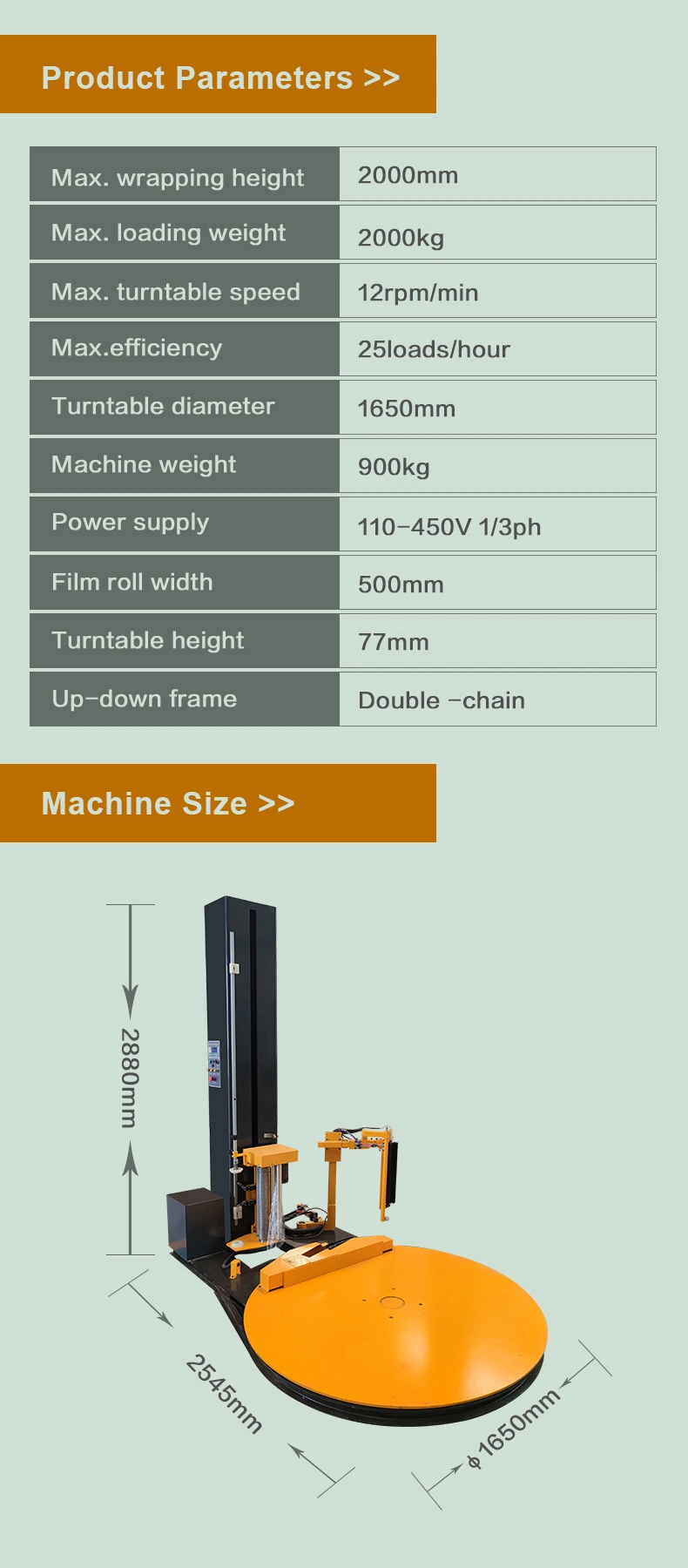

Package size per unit product 254.50cm * 165.00cm * 288.00cm Gross weight per unit product 900.000kg Fully-auto Pre-stre

Basic Info

| Model NO. | T1650FZ |

| Application | Beverage |

| Automatic Grade | Automatic |

| Inclusion Degree | Fully Wrapped Winding Machine |

| Structure | Pallet Wrapping Machine |

| Film Frame Structure | Pre Tension |

| Series | T Series - Pallet Wrapping Machine |

| Max. Wrapping Height | 2000mm |

| Max.Loading | 2000kg |

| Carriage up&Down Speed | Adjustable |

| Efficiency | 25loads/Hour |

| Turntable Diameter | 1650mm |

| Transport Package | Export Standard Wooden Case |

| Specification | can be customized |

| Trademark | YUPACK |

| Origin | China |

| HS Code | 84224000 |

| Production Capacity | 100/Month |

Packaging & Delivery

Package size per unit product 254.50cm * 165.00cm * 288.00cm Gross weight per unit product 900.000kgProduct Description

Fully-auto Pre-stretch casting film wrapping machine/winding packaging machineT1650FZ Fully automatic pre-stretch pallet wrappers is a traditional turntable type machine that has been designed to be as automatic as possible. Once the film has been loaded into the film jaw clamps there is no need to attach the film to the pallet in the normal way. At the end of the cycle the machine cuts the film with a hot wire, secures the tail end on to the pallet and then grips the film ready for the next load. It even comes with a remote control so if loaded by a lift truck the driver does not have to get out of his vehicle.

Main characteristics:

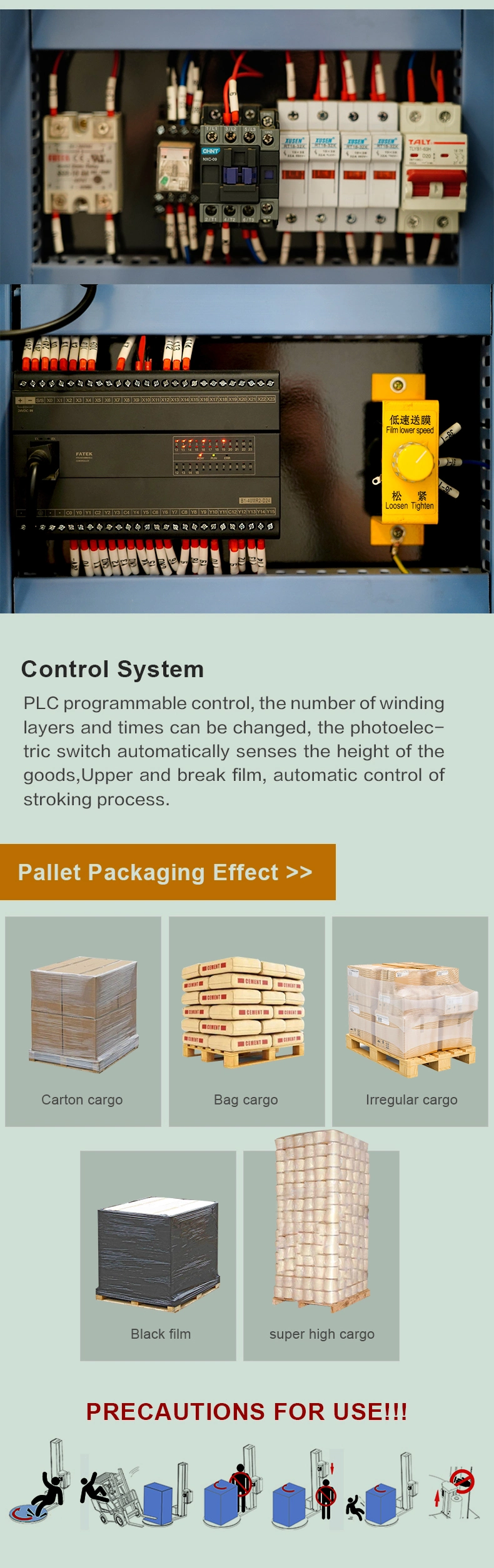

The Control Systerm

*PLC programmable control.

*The top and bottom winding layers and numbers,crossing the top time, reinforcement plies 0-9 can directly set on the panel.

*Simple operation: just press the automatic function button, can complete the whole packaging process.

*Photoelectric switch, automatic sensing cargo height.

*Excellent selection of electrical control components, high reliability.

*Automatic and manual conversion at any time.

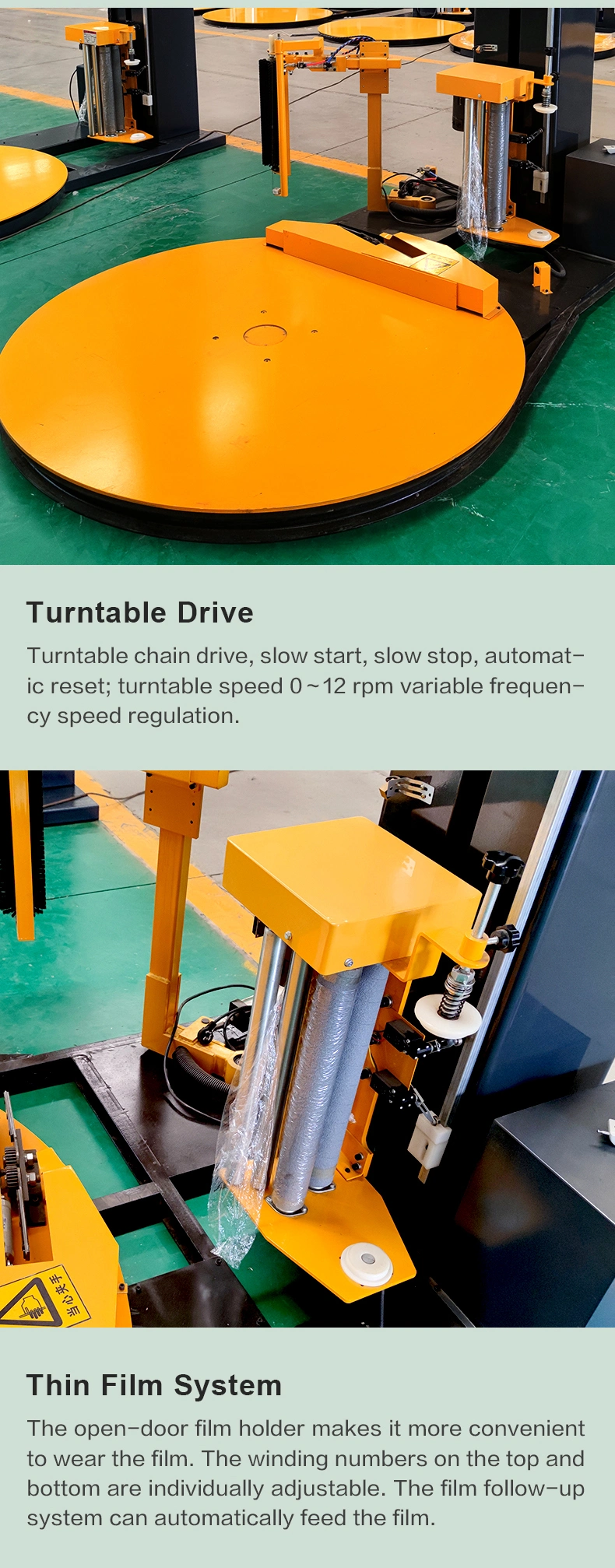

Turntable System

Rotary variable speed 0-12 rpm adjustable by frequency changer.

The turntable automatically reset when packaging finished over.

The turntable select the pure steel high wear-resistant material.

Film Delivery System

The film carriage for dynamic pre stretching mechanism, stretching up to 250%, reduce the film consumption.

Film feeding speed is adjustable, separate DC motor control.

The film frame rising and falling speed alone adjustable.

The film frame is the pure aluminum film frame, light and stable.

Selection of wear resistant rubber roller, long service life.

Film system with servo mechanism, pull.

The lifting column is double chains structure, stable and reliable.

Optional Function

The open film frame:Ease to wear membrane and replace membrane volume.

Ramp: easy to use trolley to carry the goods.

Film automatic installing and breaking.

Technical Parameters

| Model | T1650FZ |

| Max. wrapping height | 2000mm |

| Max. loading weight | 2000kg |

| Max. turntable speed | 12rpm/min |

| Max.efficiency | 25loads/hour |

| turntable diameter(standtard machine) | 1650mm |

| Machine size | L2545mm*W1650mm*H2880mm |

| Machine weight | 900kg |

| Power supply | 110-450V 1/3ph, 110-450V 1/3ph |

| Film roll width | 500mm |

| Turntable speed | 0-12rpm Adjustable, speed adjustable |

| Turntable height | 77mm |

| Up-down frame | double -chain |

Our Services

(1)Quality of pallet wrapping machine ?

We always test the machine one by one, make sure it works well before leaves our factory.

We will supply technical support and heading method or make a video show you when you need help if you have any question.

We offer 12 mouths guarantee, during this period we offer free repalacement after confiring that it is our quality problem.

(2)Customer's Training Services

We can train your staff to use your operation system properly. It mean that we offer customer training, teaching how to use the system most efficiently and safely as well as how to maintrain optimal operational productivity.

(3)Need special design of our pallet wrapping machine?

No problem, Our design team could solve it, just show your ideas, we could let it come ture.

(3)Shipping?

We will follow up the shipping until goods arrive at your hand safely. we could also do CIF trade terms including shipping directly to you even though you don't know how to import the goods to your country.

About Us

Qingdao Ausense was established in 2001,which is professionally specialized for the planning of complete end-of-line packaging equipment, R & D and manufacturing. After years of practice, we have automatic carton forming,carton package, sealing, shrinking, vacuum,strapping, palletizing, wrapping, transportation and other 10 series that are over 60 varieties of packaging equipments. Company rely on the automation industry chain advantages, the integration of technology research and development, design, production, in conjunction with the customer site applications, providing customers with intelligent, flexible, one-stop information technology automated packaging solutions.

Ausense Company flagship brand "YUPACK".we provide vacuum machine, strapping machine,etc Chinese patents. All products had passed the European CE certification; manufacturing plants involved in the Chinese machinery industry standard "mechanical strapping machine""carton sealer" drafting; Axiomtek products are widely used in Chinese companies and some well-known Fortune 500 companies, the product exported to Europe, America, Southeast Asia more than 30 countries.

In 2016 year,Qingdao Ausense has introduced into the robot, after packaging machinery unit, becoming the modular standard configuration equipment, can effectively integrate into the enterprise application MES manufacturing execution system, it is possible to provide complete automation industry from 3.0 to 4.0 transformation and upgrading services to multi-industry.

Send to us