High Barrier Food Grade 5 Layers PA/PE/EVOH/PVDC/EVA Packaging Shrink Film

Basic Info

| Material | PEVA |

| Usage | Packaging Film, Food&Medicine Film |

| Type | Shrink Film |

| Transparency | Transparent |

| Hardness | Soft |

| Processing Type | Multiple Extrusion |

| Packing | Standard Package |

| Package | Packaging Box |

| Printing | Printing Method Applicable |

| Packaging | Wound Roll Packed |

| Key Words | Vacuum Sealers |

| Keyword | Plastic Wrap |

| Advantage | Anti Fog |

| Product Name | Shrink Wrap Stretch Film |

| Use | Food Wrapping |

| Transport Package | Packaging Box |

| Specification | As required |

| Trademark | JHG BRAND |

| Origin | Jiangsu, China |

Packaging & Delivery

Package size per unit product 50.00cm * 15.00cm * 10.00cm Gross weight per unit product 1.000kgProduct Description

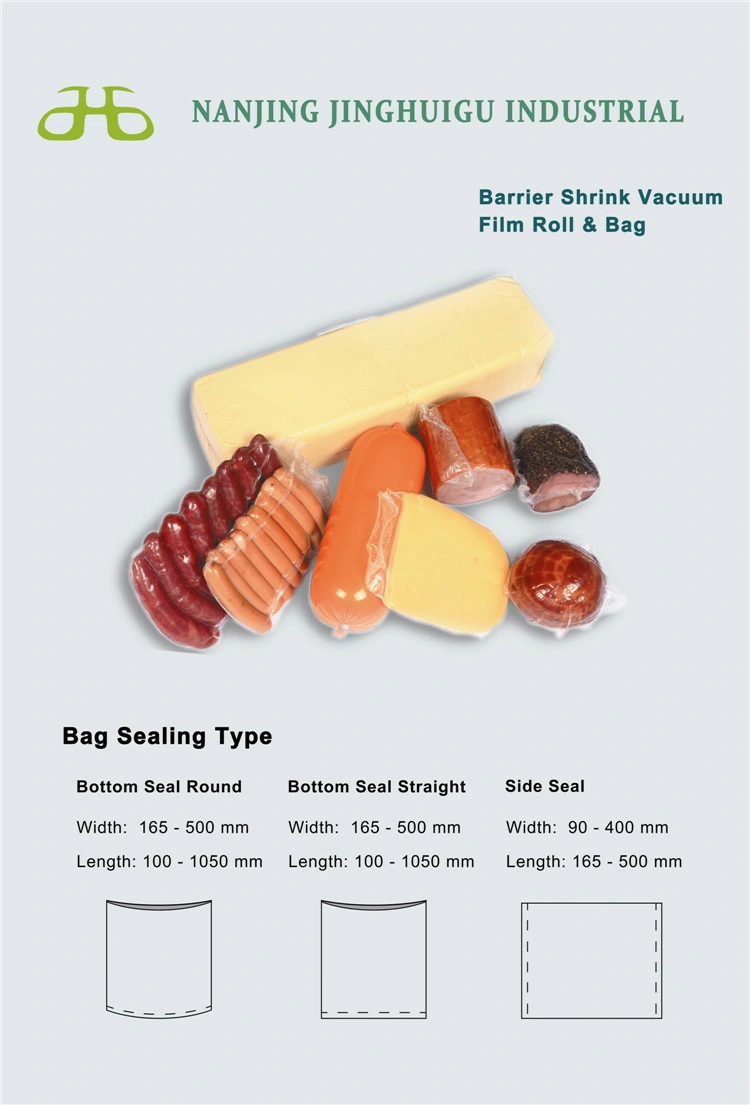

JHG Barrier Shrink Film

JHG's barrier shrink films are based on PA/PE or EVOH materials. They are available of different sizes for a wide range applications and packaging requirements. All shrink films have been tested by SGS according to REACH, FDA standards etc., and meet the regulations of contacting directly with foods.

| Application | seafood, meat, dairy, poultry, nuts, medical, electronics products |

| Structur e | 5/7 layer PA/PE co-extruded |

| Material | PA, PE, EVOH or PVDC/PE or PA/PE or EVA/PE |

| Width | within 1400mm |

| Thickness | 40-300mic |

| Freeze Resistance | -40°C |

| Heat Sealing Temp | 120°C-160°C |

Application:

1. Fresh Meat, Poultry, Processed and Smoked Meat Packaging

Moisture can be maintained to prevent the loss of fresh water and color from becoming darker.

Prevent fat from oxidation, decay and changing it's fresh color.

Vacuum packaging and cold storage can improve the curing process of the meat, making the taste more juicy.

To keep apart from oxygen to maintain the natural color of fresh meat for more long time.

2. Cheese Packaging

The lower shrinkage temperature make it more suitable for products such as cheese which need the less temperature. It looks more attractive for the character of transparency and luster.

3. Seafood Packaging

Oxygen can be blocked and inhibiting the propagation of aerobic bacteria. Vacuum-packed while storage at a low temperature ( below 4ºC) can inhibit the reproduction of anaerobic bacteria , which ensure the food healthy.

Established in 2004, Nanjing Jinhuigu Industrial Trade is a specialized supplier of packing materials, packing machinery, plastic processing equipment and other materials.Specifically, our main products include polyolefin/PVC shrink film, PVC cling film, PE stretch film, and other packing material. Moreover, we are also cooperated with qualified manufacturers to making plastic processing equipment according to the requirement of clients, such as triple bubble line for producing barrier shrink film, slitter and folder, and special wrapping shrink equipment.Since the establishment, we have been devoting ourselves to developing various sources according to the requirement of our clients. We are not only importing and exporting various products as an authorized agent from manufacturers, but also a representative of some North American and European companies in China. We have obtained good reputation and built excellent relationships with various manufacturers both domestic and overseas.Presently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Packaging & Shipping

1. Wrap the film roll with clear PE film: dust-proof 2. Put paperboard and plastic cover at two edges of the rolls: protect the paper core and the edges of films. 3. Put the roll in a quality carton box to protect the film. 4. put packed cartons on pallets, and wrap the pallets well. 5. Put pallets in container, use rope and air bag to buffer the pallets.

Our Services

1,Print special pattern.

2,Making high barrier bags.

3,hot needle perforation film.

4,Anti-fog film.

FAQ

1, Q: Do you accept OEM?

A: Yes, we do.2, Q: What's your delivery time?

A: 15-35working days .3, Q: What's your production capacity?

A: About 20 ton per day.4, Q: What's your payment term?

A: We accept T/T, L/C, Western Union, Paypal, and Cash.5, Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.6, Q: How can we know whether the quality is good or not?

A:We can arrange you free sample and our certificates .