Printed BOPP/CPP Roll Plastic Film Sheet Coil Slitting Machine Made in China

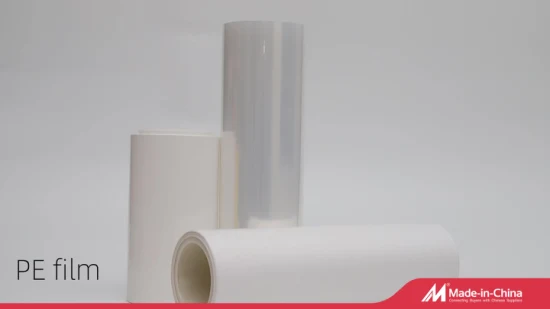

High Speed Slitting Rewinding Machine(HQJ-1300) Features:This machine is used to cut all kinds of roll materials such as

Basic Info

| Model NO. | HQJ-1300/1500/1700 |

| Application | Commodity |

| Type | High-Speed Slitting Machine |

| Work Method | Round Knife Cutting |

| Structure | Frame Part |

| Packaging | Film |

| Classification | Paper and Film Cutting |

| Applicable Process | Process Materials |

| Suitable Substrates | Paper |

| Packaging Material | Wood |

| Slitting Speed | 400m/Min |

| Machine Color | White or Customized |

| Delivery Time | 40days |

| Machine Warranty | One Year |

| Voltage | 380V 50Hz or Customized |

| Feeding Roll Width | 1300/1500/1700mm |

| Transport Package | Wooden Case |

| Specification | 1300/1500/1700 |

| Trademark | Keepon |

| Origin | China |

| HS Code | 844110000 |

| Production Capacity | 400sets/Year |

Product Description

High Speed Slitting Rewinding Machine(HQJ-1300)Features:This machine is used to cut all kinds of roll materials such as BOPP, PET, CPP and PVC Etc.1.Imported PLC integrated control is used in electrical control system, human-machine communication is carried out by touch screen, Set and display working parameters according to the requirements from different products.2.Vector frequency-converting is adopted for rewinding, roll diameter is automatically calculated by PLC to achieve automatic tension control.3.Magnetic powder brake is adopted for unwinding, roll diameter is automatically calculated by PLC to achieve automatic tension control.4.Non-shaft pneumatic system for unwinding section is used. convenient load and unloading, high efficiency, automatic correction for unwinding (hydraulic automatic feeding is optional) .5.Double tensioning shafts are used for rewinding, straight knife is used for slitting, smooth for the surface, and there is air suck fan device for waste edge.6.In the system, there are calculations of meter, roll diameter, calculations of meter automatic machine stop etc.7.The system has perfect mechanic, electric and pneumatic design, also good safety protection.8. There are many different model such as 1300,1500,1700mm available slitter rewinder.Technical Parameter:

| Model | HQJ-1300 |

| Width of raw material | 1300mm |

| Max. Diameter of unwinding | Φ600/800mm |

| Slitting and rewinding speed | 400m/min |

| Max. Diameter of rewinding | 500mm |

| Slitting and rewinding width | 30-1300mm |

| Error correction accuracy | ±0.4mm |

| Thickness of raw material | 0.012-0.2mm |

| Weight of machine | 3500kg |

| Total power | 9kw |

| Overall dimensions(L×W×H) | 2500×4200×2000mm |

Our Plant View:Packing And Shipping:

Clients And Exhibition:

FAQ

1.

Q: What is your delivery term?

A: FOB,CIF,CFR usually.

2

Q: What is your payment?

A: T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

3

Q: What is your delivery time?

A: 30-50 days usually

4

Q: What is your warranty and other terms?

A: One year machine warranty,and whole life technical support. Spare parts are free for customer in 1 year.

We can send our engineer to your factory for machine installation and operator trainning if you need,

Customer pay the flight tickets,meals and hotel for our engineer.

Salary USD100.00 per day to our engineer.

Send to us